DESIGN AND MAKE

FROM SKETCH TO DESIGN / CUT /AND ASSEMBLE.

IF YOU HAVE A CUTTING LIST.

OR

THROUGH VARIOUS SOFTWARE A DESIGN FOR CASE GOODS WITH DIMENSIONS OF EACH PART CAN BE PRODUCED.

A TOOLPATH CAN BE GERERATED FOR CUTTING.

YOU CAN ALSO MANNIPULATE THE DRAWINGS AND HAVE PILOT HOLES MARKING,

INDICATING WHERE VARIOUS FITTINGS FOR DRAW RUNNERS / BALL BEARING DRAW SLIDES TO BE LOCATED.

AND EVEN MACHINE POT HOLES HINGES FOR YOUR DOORS.

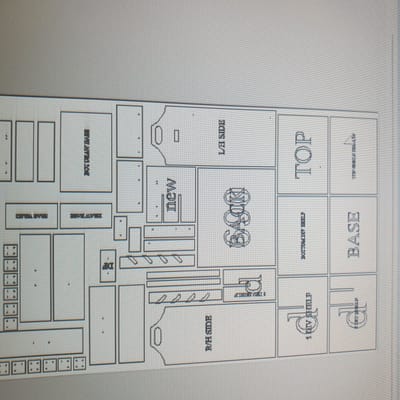

EXAMPLE

I DESIGNED A MOVABLE TROLLEY FOR THE CRICUT MACHINE.

FROM SKETCH TO DESIGN AND CUT

ALL PARTS WERE CUT ON THE CNC AND ASSEMBLED.

ALL MY BALL BEARING DRAW SLIDES HAD PILOT HOLES INDICATING WHERE TO BE PLACED I ALSO DRILLED 4MM HOLES FOR THE HANDLES .

SEE ABOVE PICTURES =(1) DESIGN CUTTING LAYOUT. (2) CNC CUTTING (3)ASSEMBLE

IF YOU HAVE A CUTTING LIST.

OR

THROUGH VARIOUS SOFTWARE A DESIGN FOR CASE GOODS WITH DIMENSIONS OF EACH PART CAN BE PRODUCED.

A TOOLPATH CAN BE GERERATED FOR CUTTING.

YOU CAN ALSO MANNIPULATE THE DRAWINGS AND HAVE PILOT HOLES MARKING,

INDICATING WHERE VARIOUS FITTINGS FOR DRAW RUNNERS / BALL BEARING DRAW SLIDES TO BE LOCATED.

AND EVEN MACHINE POT HOLES HINGES FOR YOUR DOORS.

EXAMPLE

I DESIGNED A MOVABLE TROLLEY FOR THE CRICUT MACHINE.

FROM SKETCH TO DESIGN AND CUT

ALL PARTS WERE CUT ON THE CNC AND ASSEMBLED.

ALL MY BALL BEARING DRAW SLIDES HAD PILOT HOLES INDICATING WHERE TO BE PLACED I ALSO DRILLED 4MM HOLES FOR THE HANDLES .

SEE ABOVE PICTURES =(1) DESIGN CUTTING LAYOUT. (2) CNC CUTTING (3)ASSEMBLE